CAPABILITIES

Design for plastics injection molding or blow molding requires a certain approach and working with Hi-Rel

Plastics saves time and money and results in suitable plastic molding designs from the outset.

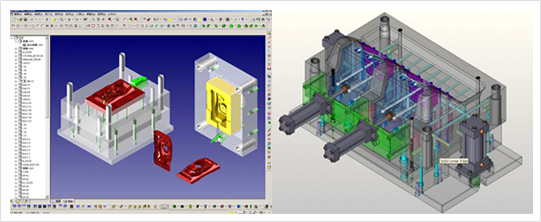

Sharing expertise with our customers, together we optimise choice of plastic material, physical shape, ease of

production, cost and performance. Working in partnership from initial concept, through the moldingdesign stage

using 3D CAD, to making of the injection mold or blow mold tool.

Hi-Rel Plastics is capable of producing rapid plastic prototypes using 3D printer which will closely resemble

the final injection molded or blow molded plastic parts enabling you to fully test the part prior to investing

in tooling.

Hi-Rel Plastics has more than 35+ years’ experience in the injection molding & blow molding of plastic

components. Advice and quotes on anything from a simple sketch to a 3D computer model. Most drawing formats can

be handled by our design department although we find STEP, IGES and DXF translate most successfully. Simply

email your drawing/model and we’ll do the rest.

To help you in the early stages of your plastic molding design we have produced a Design Guide with general

advice on designing products and components for plastic injection molding.