What Is 3D Printing?

At its most basic, 3D printing is a manufacturing process in which material is laid down, layer by layer, to form a three-dimensional object. Although 3D printers employ a variety of materials (such as plastic or metal) and techniques, they share the ability to turn digital files containing three-dimensional data—whether created on a computer-aided design (CAD) or computer-aided manufacturing (CAM) program, or from a 3D scanner—into physical objects.

Hi-Rel Plastics & Molding, Inc. is your premier source for product development services. From the design stage, to prototyping, to manufacturing, you can depend on our team to provide exceptional solutions that will bring your next big idea to reality. Get to know us!

Rapid Prototyping Service

At Hi-Rel Plastics & Molding, Inc., we specialize in the production of high-quality, low-cost prototypes. With a range of technologies and services, we are the perfect one-stop-shop for all your prototyping needs. When you’re ready, we also provide low-volume manufacturing of 100,000+ parts. Continue reading to learn more about the rapid prototyping process or send your 3D design file to our team of engineers for a free quote.

What Is Rapid Prototyping?

Rapid prototyping involves specialized manufacturing techniques for making high-quality physical models of a 3D design idea. Prototypes are useful for design improvement, as stepping stones to full production or for engineering testing. They are meant to be quick and economical, without the need for the investment in hard tooling. Many of our clients need to produce a physical part quickly in order to validate a design or to capture a fleeting sales opportunity.

Advantages Of Making A Prototype

How can making a prototype help you and your business? Here are just some of the ways:

• Show your customers and investors a physical model of your product

• Demonstrate the appearance, dimensions and features of your product

• Test the market with your product before production

• Save time and money by identifying and reducing design flaws

• Improve and streamline the production process

• Create multiple versions with different colors, surface textures and finishing processes

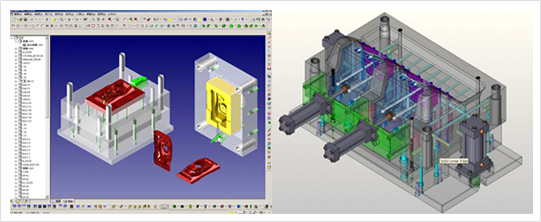

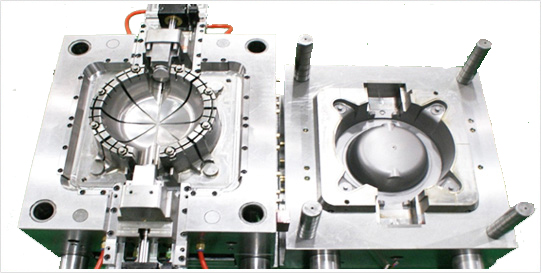

Plastic mold tool and die manufacture is offered in-house, providing you with cost effective mold-making.

Hi-Rel Plastics & Molding, Inc. also has long established relationships with a number of subcontract toolmakers in US, China & Korea so offering maximum flexibility. Tooling manufactured by one of our partners is managed as in-house in accordance with our specifications. Working closely with the design and production teams our tool making experts do not approve the injection mold until they are sure of optimum performance.

Should your tool require emergency attention, our on-site facilities ensure minimum disruption to the production process. Modifications to the tooling can be carried out quickly and economically with plastic injection molding & blow molding technical support provided all the way.

Ongoing preventive tool maintenance is carried out free of charge for all injection molds & blow molds manufactured by us or by one of our partners for its entire working life all the time Hi-Rel Plastics is the appointed molder.

Tools are also stored and insured against Earthquake (fire and shock risks), Fire, Lightning and Explosion free of charge.

If you have any existing mold tool or suite of tools and are looking for a new injection molder or blow molder , Hi-Rel Plastics will adapt these tools for our molding machines and produce sample parts at minimum charge. If any refurbishment is required, this can be carried out quickly and cost effectively in our own tool room.

Hi-Rel Plastics & Molding, Inc. offers custom plastic injection molding and blow molding for all major industries. At Hi-Rel Plastics & Molding, Inc. we serve every facet of the molding process from part evaluation, tool design, prototyping, tool making, sampling and production of quality finished parts. Our commitment to product quality, on-time delivery, and superior customer service has enabled us to forge strong.

Hi-Rel Plastics & Molding, Inc. processes an almost infinite variety of thermoplastic resins, including engineering grade materials such as PEEK, ULTEM, PVDF, LCP, PPS, PES, PC, PBT, ABS, NYLON, ACETAL, PP, HIPS, HDPE, LDPE, ELASTOMERICS (TPE), POLYURETHANES, ACRYLIC, PVC and many other specialty filled / unfilled grades too numerous to list. Since we started the business in 1984, we've built partnerships with every customer on the basic business principles of integrity, responsibility and ingenuity.

Whether you’re looking for complex technical parts for medical, aerospace, military or scientific application or luxury item components for your high end customers, the mold designed & build by Hi-Rel Plastics & Molding are always very high precision.

With more than 35+ years of experience, our employees master technical & practical knowledge of design & building of molds & injection of plastic parts. Our team has acquired a level of technical skill & problem-solving experience that guarantees the delivery of high quality products to our clients. Some of the parts we make here we have to meet tolerances of up to ± 0.001 inch in order to maintain a low rejection rate of less than one-half percent.

WHY US?

• 35+ years of thermoplastic injection and blow molding experience.

• ISO 9001:2015, AS 9100 Rev D, 13485:2016 Certified

• ISO 7 (Class 10,000) Type Clean Room Manufacturing Space

• Consistent high-quality parts at competitive prices.

• Environmentally clean facility.

• Engineering Solutions for demanding applications.

• Encompass all of the offerings of the business. ( Part Design, Mold Making,Thermoplastic Molding, Electronic Assembly, Value Added Secondary Services)

• We offer JIT ( KANBAN ) orders.

• We utilize our own fleet of delivery vehicles to ensure accurate just-in-time delivery.

• We invest in training associates through a full-time trainer and pay-for-knowledge training system to ensure associates continue to learn and maintain industry skill levels.

• We are a team of dedicated Associates ready to serve your injection and blow molding needs.

• Our quality is superb, price is competitive, and delivery is the best in the industry.

• Hi-Rel Plastics Molding, Inc. is serious about providing customer service.

Has your current plastic injection molder ceased trading? Are you receiving an unreliable service or poor quality plastic injection moldings?

Hi-Rel Plastics would be happy to undertake your plastic injection molding work. We have vast experience of taking existing mold tools and producing the high quality moldings you require.

Whether it is just one mold or a whole suite we can assess the tools in our own tool room and undertake any necessary repairs or refurbishment quickly. Adapting plastic mold tools for our molding machines, if necessary, will be carried out as soon as the tools arrive allowing speedy production of samples prior to production.

We have a wide range of injection molding machines and can offer machining and assembly if required.

Please contact us by ‘phone, fax or email to discuss your requirements.

Don’t put up with poor quality or unreliable service any longer.

Blow molding is the process of forming a molten tube (referred to as the parison or preform) of thermoplastic material (polymer or resin) and placing the parison or preform within a mold cavity and inflating the tube with compressed air, to take the shape of the cavity and cool the part before removing from the mold.

Any hollow thermoplastic part can be blow molded.

Parts are not just limited to bottles, where there is one opening and it is usually smaller in diameter or size than the overall body dimensions. These are some of the most common shapes used in consumer packaging, however there are other typical types of blow molded parts, including, but not limited to:

• Industrial bulk containers

• Lawn, garden and household items

• Medical supplies and parts, toys

• Building industry products

• Automotive-under the hood parts

• Appliance components

History of Blow Molding

The basic concept of blow molding comes from the glassblowing process. As early as the 1880’s there was a patented method of extruding a Celluloid polymer into a parison and blow molding a part. Early methods and materials to blow plastics into shapes were very crude and not suitable for mass production. It wasn’t until the late 1930’s that the first commercial machines and products were developed for the manufacturing of blow molded bottles. The major event that triggered and fueled the early years of commercial blow molding was the development of low and high density polyethylene suitable for blow molding and consumer packages. From this, there was an explosion of blow molded products and equipment in both Europe and North America.

Blow Molding Manufacturing Processes

There are three main types of blow molding:

• Extrusion blow molding

• Injection blow molding

• Injection stretch blow molding

The main differences among them are the method of forming the parison; either by extrusion or injection molding, the size of the parison and the method of movement between the parison and blow molds; either stationary, shuttling, linear or rotary.

In Extrusion Blow Molding-(EBM) the polymer is melted and the solid extruded melt is extruded through a die to form a hollow tube or parison. Two halves of a cooled mold are then closed around the parison, pressurized air is introduced through a pin or needle, inflating it into the shape of mold, thus producing a hollow part. After the hot plastic has cooled sufficiently, the mold is opened and the part is removed.

In EBM there are two basic methods of extrusion, Continuous and Intermittent. In continuous, the parison is extruded continuously and the mold moves to and away from the parison. In Intermittent, plastic is accumulated by the extruder in a chamber, then forces through the die to form the parison. The molds are typically stationary under or around the extruder.

Examples of the Continuous Process are Continuous Extrusion Shuttle machines and Rotary Wheel machines. Intermittent extrusion machines can be Reciprocating Screw or Accumulator Head. Various factors are considered when selecting between the processes and the size or models available.

Examples of parts made by the EBM process include many hollow products, such as bottles, industrial parts, toys, automotive, appliance components and industrial packaging.

With respect to the Injection Blow Systems – (IBS) process, the polymer is injection molded onto a core within a cavity to form a hollow tube called a preform. The preforms rotate on the core rod to the blow mold or molds at the blowing station to be inflated and cooled. This process is typically used to make small bottles, usually 16oz/500ml or less at very high outputs. The process is divided into three steps: injection, blowing and ejection, all done in an integrated machine. Parts come out with accurate finished dimensions and capable of holding tight tolerances—with no extra material in the formation it is highly efficient.

Examples of IBS parts are pharmaceutical bottles, medical parts, and cosmetic and other consumer product packages.

Injection Stretch Blow Molding- (ISBM) the Injection Stretch Blow Molding- (ISBM) process is similar to the IBS process described above, in that the preform is injection molded. The molded preform is then presented to the blow mold in a conditioned state, but before final blowing of the shape, the preform is stretched in length as well as radially. The typical polymers used are PET and PP, that have physical characteristics that are enhanced by the stretching part of the process. This stretching gives the final part improved strength and barrier properties at much lighter weights and better wall thicknesses than IBS or EBM—but, not without some limits such as handled containers, etc. ISBM can be divided into the One Step and Two Step process.

In the One Step process both preform manufacture and bottle blowing are performed in the same machine. This can be done in 3 or 4 station machines, (Injection, Conditioning, Blowing and Ejection). This process and related equipment can handle small to high volumes of various shape and size bottles.

In the Two Step process the plastic is first molded into the preform using an injection molding machine separate from the blow molder. These are produced with the necks of the bottles, including threads on the open end of the closed end hollow preform. These preforms are cooled, stored, and fed later into a re-heat stretch blow molding machine. In the Two Step Reheat Blow process, the preforms are heated (typically using infrared heaters) above their glass transition temperature, then stretched and blown using high-pressure air in the blow molds.

The Two Step process is more suited to very high volumes of containers, 1 liter and under, with very conservative use of resin providing great strength, gas barrier and other features.

Materials suitable for Blow Molding

Examples of Blow Molding Polymers in single layer or multiple layer structures or combinations include such materials as:

(i) High Density Polyethylene,

(ii) Low density Polyethylene,

(iii) Polypropylene,

(iv) Co-polyester,

(v) PET,

(vi) PVC,

(vii) Nylon,

(viii) EVOH,

(ix) EVA,

(x) TPE,

(xi) COP and COC,

(xii) Polycarbonate,

(xiii) Polystyrene,

(ix) ABS, etc.

Hi-Rel Plastics & Molding Corps’ ISO 7 (Class 10,000) type clean room manufacturing space is ideal to accommodate your controlled environment needs. Our certified cleanroom offers the following capabilities to support your medical or aerospace project development & production molding programs:

• Close Tolerance Injection Molding Services.

• Injection molding press capacities ranging from 35 to 350 ton.

• Vertical injection molding to support your insert and over-molding needs.

• Post-mold Processes and Product Assembly.

• Specialized Packaging Services.

• Complete Tooling Services

Hi-Rel Plastics & Molding, Inc.’s Micro Molding specializes in micro injection molding and micro mold tooling, producing millions of zero-defect micro parts each month for customers in the medical, pharmaceutical, microfluidics, electronics/office automation and automotive industries.

Our micro injection molding capabilities include clean-room, high-temperature, thin-wall, two-shot and over-molding, and the high-precision plastic injection molds we provide are designed and custom built to hold tolerances as small as ±5 microns (0.0002 in).

Hi-Rel Plastics & Molding, Inc.’s 24/7 plastic injection molding facility in Riverside CA is ISO 9001-2015, ISO ISO13485:2016, ISO AS 9100 REV D certified with ISO 7 Class 10,000 Clean Room, It combines:

• Advanced injection molding machines with highly sophisticated process/quality control capabilities

• Proprietary production monitoring cameras and systems

• Customized precision robotics, automation and packaging systems

In addition to a wide range of plastic engineering resins, we are experienced in micro molding high-temperature materials (to 806°F).

From concept, design and rapid prototyping, to precision tooling and production, we can help tackle the toughest micro part challenges and meet your manufacturing quality, delivery and cost-containment requirements.

Hi-Rel Plastics & Molding, Inc. utilizes liquid injection molding (LIM) using liquid silicone rubber (LSR) to manufacture molded silicone parts, gaskets. Utilizing its extensive experience with LIM and LSR, Hi-Rel Plastics & Molding, Inc. has selected the top performing liquid silicone rubber materials and processes for these custom components. LSRs are injection molded with faster cure cycles than gum base silicones. LSR components are UV and ozone resistant and have excellent water sealing properties. Liquid silicones can be molded into intricate parts with thin or thick cross sections.

Benefits of Liquid Injection Molding (LIM)

Faster cure cycles are a key benefit for specifying LSR for molded gaskets and seals. Cure cycles of 30 to 60 seconds are typical for small gaskets and cushioning components with thin cross-sections. This means a single or two cavity liquid injection mold can out-produce a multi-cavity compression mold due to the 6 to 8 minute cure cycles that are typical of gum base silicones. Fewer cavities in the liquid silicone mold can improve tooling lead times and improve dimensional consistency.

Benefits of Liquid Silicone Rubber (LSR)

Hi-Rel Plastics & Molding, Inc. uses platinum cure silicone compounds to make injection molded parts. Some key features that make LSR the material of choice for many applications include:

• Wide hardness range of 10 to 80 durometer Shore A

• Wide operating temperature (-58°F to 392°F)

• Good elongation properties

• Excellent electrical insulation

• Excellent UV and ozone resistance

• Excellent for outdoor environmental sealing

• Good for submerged sealing uses (IP67 and NEMA 6)

• Good material for low temperature cushioning (cold drop test)

• Many available standard colors and custom colors for molded parts

Insert Molding is when plastic is injected into the mold cavity and insert piece (or pieces mostly brass or stainless steel metal components) prior to plastic injection molding. The resulting product is a single piece with the insert encapsulated by the plastic.

Benefits:

• Faster Assembly Time

• Reduced Part Size

• Reduced Part Weight

• Cost-Effective

Product Examples:

• Filters with Fine Mesh Inserts

• Vacuum Hose Connectors

• Automobile Air Ducts

• Heavy Equipment Components

• Medical Syringes

Overmolding is when one material being is molded over a second material.

The base layer is molded first and the additional plastic layer(s) are molded over and around the original part – resulting in a single, finished product.

Benefits:

• Strong Finished Product

• Long Service Life

• Enhanced Safety

• More Cost Efficient than Post-Molding Fabrication

Product Examples:

• Soft over hard material Cell Phone Cases

• Power Tools & Hand Tools

To avoid plastic molding defects like distortion, gaps and stress fractures, molds must be meticulously designed and the overmolding process must be performed with utmost precision.

Whether you are using metal or plastic resins, proper material selection is critical to ensure materials bond together chemically and mechanically – without experiencing molding defects like melt or distortion.

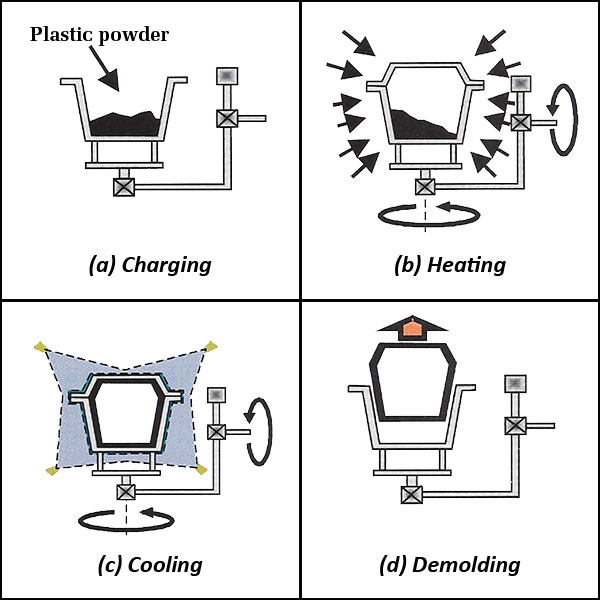

Rotational molding, also known as rotomolding, is a plastics molding technology which is ideal for making hollow articles. It is a casting technic but unlike most other plastics processes there is no pressure involved. Molds for the process are relativelyinexpensive as they do not have to withstand pressure and therefore relatively short production runs can be made very economically.

Rotomolding is used to make a very diverse range of products. The process offers the product designer exceptional freedom as just about any shape can be produced. There is almost no limit to the size of moldings and there are literally thousands of applications.

The Process

The concept of rotational molding is very simple. A plastic material, normally in powder form is placed into a hollow mold, usually made from cast aluminium or fabricated from sheet steel. The mold is closed and rotated slowly on two axis. The mold is then heated in an oven whilst rotating and the polymer gradually melts and ‘lays-up’ on the inside of the mold. Once the polymer powder has fully melted the mold is moved to a cooling station and cooled usually with air and sometimes a fine mist of water. As the mold cools the part solidifies. When the material has finally cooled sufficiently to release away from the mold surface the process is stopped and the product is taken out of the mold (de-molded).

Whilst the concept of rotational molding is extremely simple anyone who has ever been involved in the process will tell you that it is in fact extremely complicated. It is a casting process and there is normally no pressure involved which means that the material cannot be controlled in the same way as high pressure processes such as injection molding. There are many variables that can affect production and the end product such as ambient temperature and humidity, type of mold, material specification and powder quality.

Materials

Today the industry is heavily dependent on Polyethylene (PE) and 97% of rotomolded products are made from this material. Polyethylene is a versatile, easily moldable and readily available polymer which has come to dominate the process. Rotomolding is a casting technique in which powder is nearly always used rather than granules, meaning the material must be ground. Polyethylene is relatively easy to grind at ambient temperatures. The development of other polymers has been hindered by the fact that the process is relatively long and therefore aggressive on polymers, however there is some usage of PVC (usually in liquid plastisol form), Polypropylene and Polyamide (PA6, PA11 & PA12). Many of these non-Polyethylene materials are difficult to grind and most need to be made into powder using cryogenic grinding – that is freeze grinding, which is a costlier process. There is a welcome increase in R&D to expand the range of materials available to the industry.

Key advantages

Rotomolding has several unique characteristics and advantages compared to other molding processes.

• Low tooling costs. As this is a casting process there is no pressure. This means molds are inexpensive and low volume can be economic. If you have a great idea for a new product but don’t know how many you’ll sell or simply want a low volume production

• Run, rotomolding’s low initial investment makes it particularly attractive.

• It’s easy to make complicated shapes. Rotomolding readily accommodates production complexities such as stiffening ribs, molded inserts and different surface textures.

• Uniform wall thickness. Rotomolding achieves consistent wall thickness with corners tending to be thicker. This increases product strength and integrity. Other processes such as blow molding stretch the molten material at corners or sharp edges creating potential thin spots and weaknesses.

• Rotational molding machine costs are low compared to other processes and the investment required is small. There is great production flexibility with the process.

• There is almost no limit to the size of products and several different products can be molded at the same time.

Products

This exceptionally versatile technology can produce a remarkable range of moldings. There are thousands of products that are rotomolded used in a multitude of sectors. Key areas include:

• Tanks for storing water and chemicals – up to 50,000 litres

• Material handling products such as containers, crates, pallets and insulated fish and cooler boxes.

• Environmental products which include litter bins, road cones, bollards, traffic dividers and road signs.

• Floats, buoys and pontoons.

• Automotive products such as truck mudguards, ducting, diesel fuel tanks, toolboxes and tractor dashboards.

• Kayaks, canoes and boats

• Products for the outdoors such as garden planters, water butts and furniture.

• Toys and playground equipment.

While other forms of plastic molding use extrusion to insert the plastic resins into the mold, extrusion molding extrudes the melted plastic material directly into the die. This process is unique in that the shape of the die, not the mold, determines the shape of the final product.

Extrusion molding is ideal for manufacturing parts with continuous length and uniform cross-sections. Similar to a plastic injection molding machine, the extrusion molding machine has a screw that turns to feed the plastic resin into the feeder. The molten plastic then moves through a die, creating a long, tubular shape. The shape of the die determines the shape of the plastic tube. Once the extrusion is cooled, it is removed from the machine.

Extrusion molding is well-suited for long, hollow-formed applications, such as tubes, pipes, and straws. Plus, manufacturers can create these parts in many different shapes, including T-sections, U-sections, square sections, I-sections, L-sections, and circular sections.

Highly productive Injection Molding systems with waste saving devices represent a large percentage of our molding activity. In addition, we specialize in low waste transfer and flashless rubber molding. When appropriate, automation is designed to complement the chosen system, resulting in higher efficiency and reduced costs. Compression molding and rubber bonded to metal and plastic substrates are two additional specialties we offer.

Compression Molding

This method is mostly used for larger parts and/or with very expensive compounds. This method utilizes less expensive tooling, but is not as precise as other methods of rubber molding. With compression molding, material is placed directly into the open cavity and then the parting lines are clamped and the part is formed.

Transfer Molding

This method is most often used for producing precision parts adhering to tight tolerances. We often incorporate hardened and self registering cavity inserts in our rubber molds to ensure perfect registration along with dimensional and flash control. With transfer molding material is “transferred” through sprues into the cavity while the parting lines are clamped and the part is formed.

The Process of Heating & Forming a Thermoplastic Material Sheet

Our thermoforming capabilities range from a high speed inline Lyle with a 30”x40” platen, to our smaller Atlas Vacs. The Lyle is a good choice for high production runs, with the capabilities of die cutting inline with 65 tons of cutting pressure and up- stacking. The Atlas Vacs are a great middle ground machine for your smaller production needs, and if you don’t want excessive capital tied up in tooling. These presses are designed to form in-line and die-cut off line and are a significant step up from a station former.

Hi-Rel Plastics & Molding, Inc.’s in house tooling capabilities are a great choice when it comes to fast turnaround times and rapid prototypes. Our two full-time engineers have over 50 years of industry experience. They can turn your concepts into realities in a short and efficient manner by providing working models and drawings.

Products we manufacture:

• Blister packs: Most customized economical packaging solution

• Packaging clamshell: Widely used for more secure packaging for consumer products, medical devices, Cosmetics, etc.

• Packaging Trays: Includes Food trays, Insert Packaging, Medical Device packaging

________________________________________

Material we use:

We specialize in forming sheet ranging from 0.010” to 0.060” thickness. Some of the materials used:

• PETG Medical grade

• APET/RPET

• Clear/white PVC

• PP/HDPE

• Colored or decorative films

• Silicone (one/two side) coated films

We also have fully equipped in-house machine shop for all your machining needs.

Our extensive machining capabilities include:

> Metal machining

> Aluminum tool manufacturing

> CNC turning & lath operation

> 5-axis CNC milling

> Secondary drilling or milling operations

> Plastics annealing for stress relief

> Ultrasonic insertion & welding

> Bonding

> Metal welding

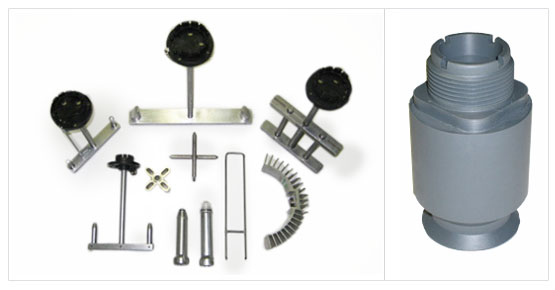

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes.

It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few. We offer metal stamping services to deliver components for industries in automotive, aerospace, medical, and other markets.

As global markets evolve, there is an escalated need for quickly-produced large quantities of complex parts. Metal stamping is a fast and cost-effective solution for this large-quantity manufacturing need. Manufacturers who need metal parts stamped for a project generally look for three important qualities:

• High quality /durability

• Low Cost

• Fast turnaround time

The following guide illustrates best practices and formulas commonly employed in the metal stamping design process and includes tips to incorporate cost cutting considerations into parts.

Stamping Basics

Stamping — also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press, a tool and die surface form the metal into the desired shape.

Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal.

Before the material can be formed, stamping professionals must design the tooling via CAD/CAM engineering technology. These designs must be as precise as possible to ensure each punch and bend maintains proper clearance and, therefore, optimal part quality. A single tool 3D model can contain hundreds of parts, so the design process is often quite complex and time-consuming.

Once the tool’s design is established, a manufacturer can use a variety of machining, grinding, wire EDM and other manufacturing services to complete its production.

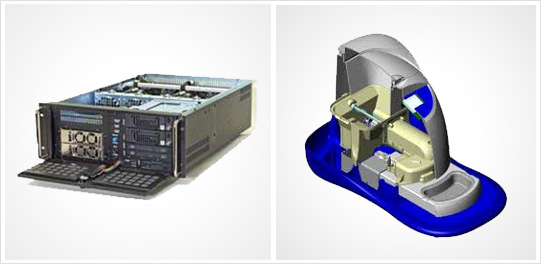

We have fully staffed plastic & electronic assembly department for all of your assembly needs like:

> Plastic parts assembly

> Product assembly

> Electronic assembly

> Chassis, mechanical and final assembly

> Cable assembly & test services support

> Labeling services

> System wiring

> Coil manufacturing

Our electronic & mechanical assembly services include:

> Surface Mount And Through-Hole Assemblies

> Small To Large Volume Production

> Prototype Boards And Assemblies

> Full Product Box Build

> Potting And Conformal Coating

> Complete, Turnkey Production

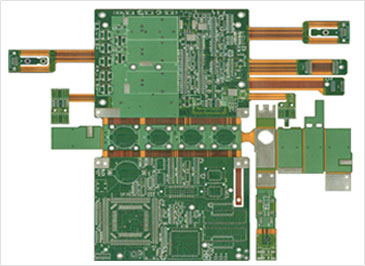

Our Printed Circuit Board Manufacturing service include:

> PCB Production

> PCB Design & Layout

> Mil Spec PCBs

> Rigid Flex PCBs

> Flex PCBs

> Prototype PCB Fabrication & Assembly

> Metal Core PCBs

> Burn-in Boards

> Lead Free PCBs

> Quick Turn Around PCBs

> Low Cost PCBs

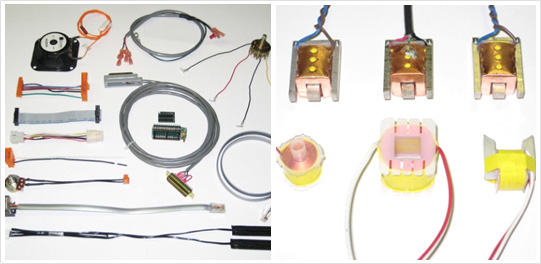

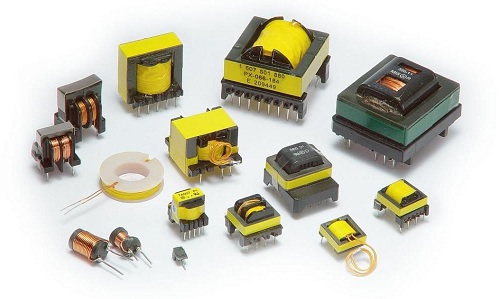

Custom Wire Winding, Custom Wire Coiling

At HI-REL PLASTICS & MOLDING, INC. we can create custom coils with smaller dimensions than traditional coils. Our proven techniques make tight tolerances, non-standard winds, tight radii, short overall lengths, and very specific pitches and diameters achievable. Whether your custom coil requires just a few turns or a few thousand, we have the expertise to deliver.

Request a quote on custom coil products, or contact HI-REL PLASTICS & MOLDING, INC. for more information.

Coil Winding to Meet YOUR Requirements

We are open to any design ideas our customers may have. Our coil winding capabilities include odd, non-standard shapes and a wide variety of other unique characteristics.

HI-REL PLASTICS & MOLDING, INC. works with wire gauges from 2 to 42, so we can produce your next project no matter how complex your design may be, or how tight the tolerances required, we welcome the challenge. HI-REL PLASTICS & MOLDING, INC. Industries specializes in turning customer designs into tangible products. We are open to any design ideas our customers may have.

What is coil winding?

The wire or conductor which constitutes the coil is called the winding. ... Each loop of wire is called a turn. In windings in which the turns touch, the wire must be insulated with a coating of nonconductive insulation such as plastic or enamel to prevent the current from passing between the wire turns."--

Coil Winding Material Options

We work with both round and flat wire in our custom coil bending and winding processes. We also possess a wide range of standard and specialty gauges to meet your needs. We carry numerous types of materials, including:

• Copper

• Aluminum

• Stainless Steel

• Brass

• And numerous specialty materials (for these contact HI-REL PLASTICS & MOLDING, INC.)

Our manufacturing expertise enables us to produce custom wound coils that exceed the standard industry callouts of the materials used. With our in-house fixturing capabilities and strategic partnerships with area machine shops, we can produce the tooling and fixturing needed to manufacture high precision, custom coils that perfectly match your specifications.

Copper Coiling Benefits

Copper coiling and coil bending services are well-suited for RF applications. Copper coiling can also transmit liquids, air, or other media to cool equipment of all types. When properly applied, copper coil winding (water coiling) can function conductively and simultaneously as a cooling coil. No matter what your application, HI-REL PLASTICS & MOLDING, INC. can create ideal copper coiling for your coil bending and winding needs.

7575 JURUPA AVE,

RIVERSIDE CA 92504

PHONE: 951-354-0258

FAX: 951-688-0497

info@hirelplastics.com