In addition to continuously improving our molding capabilities, Hi-Rel Plastics & Molding, Inc. have years of experience in proven advanced molding technologies like

What is CNC Machining?

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process that involves using high speed, precision machines to remove plastic or metal from a block (“blank”) to create the design of a part. A CNC machine takes a specific set of code and uses that to cut out a part from a blank. The CNC machine code has a list of specific instructions on how to create the part. For example, the code will start off telling the machine where to place the tooltip, how fast the tooltip should spin and to what coordinates the tooltip should move to (CNC machines use coordinates on a set axis such as x, y and z axis). Machines commonly controlled in this manner include vertical milling machines, horizontal milling machines, lathes, routers and grinders. With CNC machining, parts can be cut out with extreme precision and can be easily replicated.

Benefits of CNC Machining

CNC Prototyping

When starting a new plastic injection molding project, plastic prototype parts ensure a product’s design is sound. For most plastic parts, a CNC machined prototype will provide exactly what is needed for testing. CNC machining allows you to test the form, fit and function of injection molded parts without having to produce injection mold tooling.

Small Production Run

Since all you need is a proper CAD file, CNC machining is perfect for a small quantity of parts. Since there is no mold to create, you save money and time by directly creating the product on the CNC machine. That makes CNC machining perfect for runs under 100 pieces (once you get over 200 pieces it becomes cheaper to produce the parts with injection molding).

Quick Turnaround Time

Unlike in plastic injection molding where a mold has to be produced first, CNC machining doesn’t have that requirement. Once your files have been uploaded and approved, production can start right away. This cuts down production time dramatically.

High Quality Parts

CNC machining has many advantages. It is a more precise process than manual machining, and it provides exact repeatability. Because the computer controls the machine movement, the machine tools can all move precisely and simultaneously on their axes to create complex, three-dimensional shapes that would be almost impossible with manual machining. These qualities make CNC machining a good manufacturing process for jobs that require a high level of precision or repetition.

For plastic parts, due to the materials available and the production process itself, CNC machining can produce more robust parts compared to 3D printing. Therefore, they can be subjected to the same conditions as the eventual injection molded production parts.

Materials for CNC Plastic Machining

CNC machining is a good choice for making prototypes and low-volume plastic parts. Since CNC machining can be done with different materials than used in the 3D printing process, for example, it is frequently used for situations where the prototype needs to be tested under the same conditions as the injection molded production parts will be subjected to, and thus made of the same material. There can also be better structural integrity of parts that are CNC machined compared to 3D printed, due to the nature of the manufacturing process.

Some of CNC plastic materials are:

• ABS

• Acetal( Delrin / Celcon )

• HDPE

• Noryl

• Nylon

• PC

• PEI

• PMMA (Acrylic)

• POM

• PTFE (Teflon)

• PVC

• UHMW

• ULTEM

CNC Machining Metal

CNC machining is a subtractive manufacturing process in which a block of metal (“blank”) is machined into the design of the final part. CNC stands for Computer Numerical Control, and it utilizes computers executing code sequences to automate the machine tools which cut the metal to the design model of the part.

In CNC milling, the blank is held stationary while tools on various axes machine the part. In CNC turning, the part spins in a lathe while being machined. CNC machining is a good manufacturing process for small volumes of metal parts, such as prototypes and low volumes.

Once your metal part is machined, we can also perform secondary processes like anodizing, plating and powder coating. You can also request tolerances tighter than our standard +/- 0.002″, or other custom processes.

Whether your CNC machined metal parts are for testing the form, fit and function of a prototype, or for a low volume of finished parts, we provide a low-cost option with a fast turnaround.

Some of CNC Metal Materials

• A36 Steel Plate

• Alloy Steel 4140

• Aluminum 2024

• Aluminum 5052

• Aluminum 6061-T6

• Aluminum 6063

• Aluminum 7050

• Aluminum 7075 T6

• Bearing Bronze C932

• Easy Forming Brass 260

• Free Machining Brass C360

• Low Carbon Steel 1018

• Stainless Steel 17-4

• Stainless Steel 303

• Stainless Steel 304

• Stainless Steel 316/316L

• Titanium (Ti-6AI-4V)

Produce beautiful, plastic parts; apply design elements to part during molding process; decoration becomes permanent part of piece; decorations should last life of part.

In the in-mold decorating (IMD) or in-mold labeling (IML) process, a preprinted label or decorated appliqué film is inserted in the open plastic injection mold and held in place via vacuum ports, electrostatic charge or other method. The plastic injection mold is then closed and the plastic resin injected to mold the part, encapsulating the decoration or label permanently within the finished injection molded part.

Color plays an important role in many plastic injection molded components. Molded-in color technology enables us to achieve color matching or produce any number of vibrant, high-quality colors and finishes that our customers wish to achieve. With molded-in color technology, pre-colored plastic resins are used in the plastic injection molding process so the plastic part emerges in the specified color and finish. This method is a superior option to painting or plating because it provides a more durable, long-lasting solution.

We use the full spectrum of colors for plastic part molded-in color, including specialty colors such as metallic, pearlescent, and metal flake. We consult with our customers on product color and decoration choices, including the cost of various color options. We also educate our customers on how molded-in color and texture options interplay in the molding process.

We offer complete color matching services and incorporate color matching into our quality control process producing long-lasting, brilliant colors and finishes to our plastic parts. Molded-in color matching results in a lower final part cost and faster part production compared to traditional methods.

Our color matching process begins with a customer-supplied sample or a Pantone color selection. We work with reputable colorant vendors to provide sample color chips for customer verification, followed by a molded sample that is verified and approved by the customer. FDA & NSF compliant molded-in coloring and flame-retardant grades are available.

With our high-quality process where coloring is integrated into the plastic molded part, there are no paint scratching or peeling issues and the finished product withstands even the harshest of environments. This environmentally-friendly manufacturing process eliminates or reduces environmental impact producing less scrap and eliminating the need for secondary painting.

Pad printing is the most versatile decorating method we offer, allowing us to decorate nearly any type of plastic in any shape. It is the method of choice whenever difficult shapes must be printed or text with tight registration is required. The flexibility of this decoration method allows product designers to focus on increasingly unique design aesthetics.

Pad printing plastic parts is replacing the application of industrial labels, especially when short-run, quick-change labels are required. Our customers are enjoying the benefits of applying printed information directly to the product, saving them time and money. This is especially cost-effective for one- or two-color applications.

Using your custom artwork and clichés, we provide a full array of pad printing services – single color, in-line multicolor pad printing, rotational pad printing, and automation for high volume pad printing projects – all in a variety of colors. We fully manage pad printing operations from start to finish, ensuring a successful outcome, even for intricate applications. Our skilled pad printing technicians have in-depth knowledge of what it takes to deliver consistent quality in pad-printed products that exceed customer expectations.

Hot stamping can be an efficient plastic part decoration method that achieves high-end results. Like pad printing, when important graphics or critical product information is accommodated during the design phase, quicker production and lower costs are realized.

Hot stamping is used to decorate raised areas, also known as tipping, where a heated die applies pressure to a hot stamping foil that is pressed against the plastic part. Foils are available in a multitude of colors and finishes ranging from matte to high gloss and specialty foils including holographic and metallic. The heat and pressure from the die transfers the pigment from the hot stamping foil onto the plastic part. Hot stamping can be used on flat and rounded surfaces, and can encompass an entire circumference or, the front and back of a surface, in one operation.

Because hot stamping is a dry process, it enables us to provide an attractive, high-end appearance on plastic parts using reflective metallic foils and high gloss opaque-colored foils – something not achievable with pad printing or screen printing inks. The unique “dry” hot stamping process is also beneficial in reducing packaging and handling costs because the decorated parts can easily be bulk packed on-line with less concerns of damage to the decorated image.

So you’ve decided on the perfect container for your product. Maybe you’ve even used our Design Services to create a unique label that will set your product apart from all the others. Well, we don’t stop there. We truly are your one stop shop. Why spend hours applying your new labels yourself? We’re already set up to handle that task, quickly and economically. Whether it be cylindrical containers or flat sided products, we can have your item delivered to you labeled and ready for market.

To many people, it may be hard to think of labeling as a “science,” but the truth be known, it takes a good amount of technical background to solve tough label applications depending on types of surfaces like metal, glass, cardboard or plastic.

At Hi-Rel Plastics & Molding Inc., we offer heat transfer decal decorating which can be a cost-effective alternative to multicolor pad printing or screen printing for plastic parts, depending on the required image size and the total quantity for the project. We are able to offer this service for small, medium, high volume and bulk orders. Heat transfer decals can be applied to many plastic materials such as polypropylene, polyethylene, PVC and acrylic. Depending upon the image size and the number of parts to be decorated, heat transfer decals can be a cost-effective alternative to other decorating methods, especially for larger orders.

What is heat transfer decal decorating?

Heat transfer decal decorating utilizes high-quality screen printed or digitally printed images on a clear carrier that are permanently bonded to a part by the heat and pressure of the hot stamping process. Since heat transfer decals are preprinted, multicolor images are transferred to the part in one pass.

Our certified facility offers capabilities to complete even the most custom of projects. Specializing in large volume rigid product printing and decorating, we will work with you to find the best solution. Contact us today to get started.

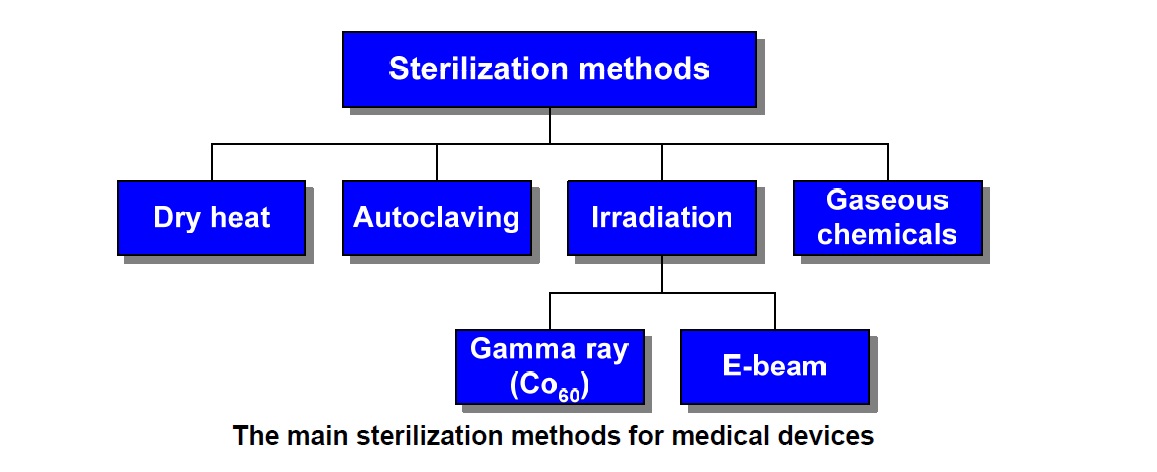

The rising use of plastics in medical devices means that the capability of being sterilized is rapidly becoming a key selection criterion for any plastic to be used in a medical device. The objective of sterilization is to prevent the introduction into the body of pathogenic organisms not normally present. Sterilization can be defined as ‘the removal or destruction of all living organisms, including resistant forms such as bacterial or fungal spores’.

Bacterial spores are most resistant to destruction, and if the sterilization is effective in eliminating bacterial spores then it can generally be assumed that all other pathogenic and non-pathogenic organisms have been destroyed. Disinfection is a lower grade of sterilization and involves only the destruction of pathogenic organisms in the vegetative (or non-sporing) state; it does not involve the destruction of spores.

Sterilization is the only acceptable standard for surgical purposes although disinfection may well be suitable for other purposes. Sterilization Methods Sterilization can be achieved through a variety of methods and these will be considered individually with particular emphasis on the applicability of the method to the sterilization of plastics devices. No matter which sterilization method is used, the objective is to reduce the bioburden (the number of microorganisms present) to a safe level. [Production in a ‘clean room’ (of any standard) does not make a device sterile; it simply reduces the initial bioburden and concentration of foreign particles to make sterilization more effective.]

The main sterilization methods for medical devices are:

• Dry Heat

• Autoclaving

• Irradiation

• Gamma Rays

• E-beam

• Gaseous Chemicals (EtO)

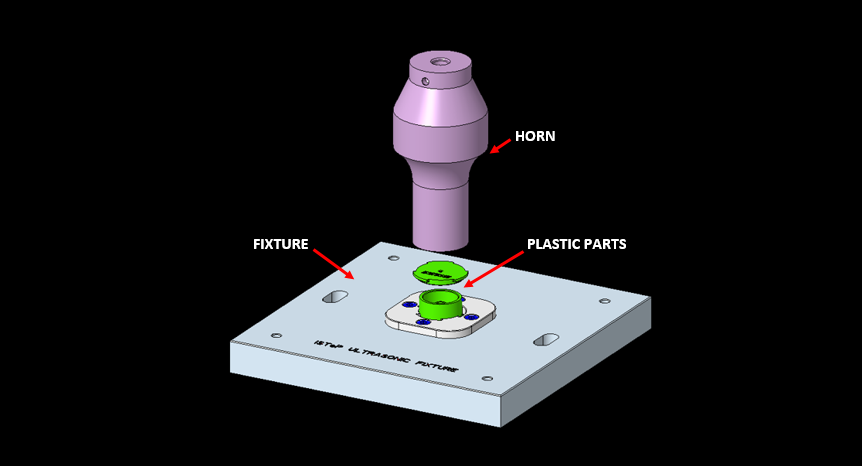

Bond metal and plastic parts together without the need for glues, adhesives or additional heating or processes; distinct advantages over other bonding processes.

The basic principle of ultrasonic assembly involves conversion of high-frequency electrical energy to high-frequency mechanical energy in the form of reciprocating longitudinal motion which, when applied to a thermoplastic, generates frictional heat at the plastic/plastic or plastic/metal interface.

In ultrasonic insertion, a metal insert is placed in a cored or drilled hole which is slightly smaller than the insert. This hole provides a certain degree of interference and also serves to guide the insert into place. The vibrating ultrasonic horn contacts the insert and the ultrasonic vibrations travel through the insert to the interface of the metal and plastic. Heat, generated by the insert vibrating against the plastic, causes the plastic to melt, and as the horn advances, the insert is imbedded into the component. The molten plastic flows into the serrations, flutes, or undercuts of the insert and, when the vibrations terminate, the plastic resolidifies and the insert is securely encapsulated in place.

In ultrasonic insertion, a slow horn approach, allowing the horn to develop a homogeneous melt phase, is preferable to “pressing” the insert. Ultrasonic insertion provides the high performance strength values of a molded-in insert while retaining all of the advantages of post-molded installation. Inserts can be ultrasonically installed in most thermoplastics.

Some of the advantages of ultrasonic inserting over other methods include rapid installation, minimal residual stresses in the component following insertion, elimination of potential mold damage, reduced mold fabrication costs and increased productivity as a result of reduced mold cycle times. In some applications, multiple inserts can be imbedded simultaneously with special horns, increasing productivity and further reducing assembly and manufacturing costs.

Ultrasonic insertion is not restricted to standard-type threaded inserts. Inserts that can be installed ultrasonically include a variety of bushings, terminals, ferrules, hubs, pivots, retainers, feed-through fittings, fasteners, hinge plates, binding posts, handle-locating pins and decorative attachments

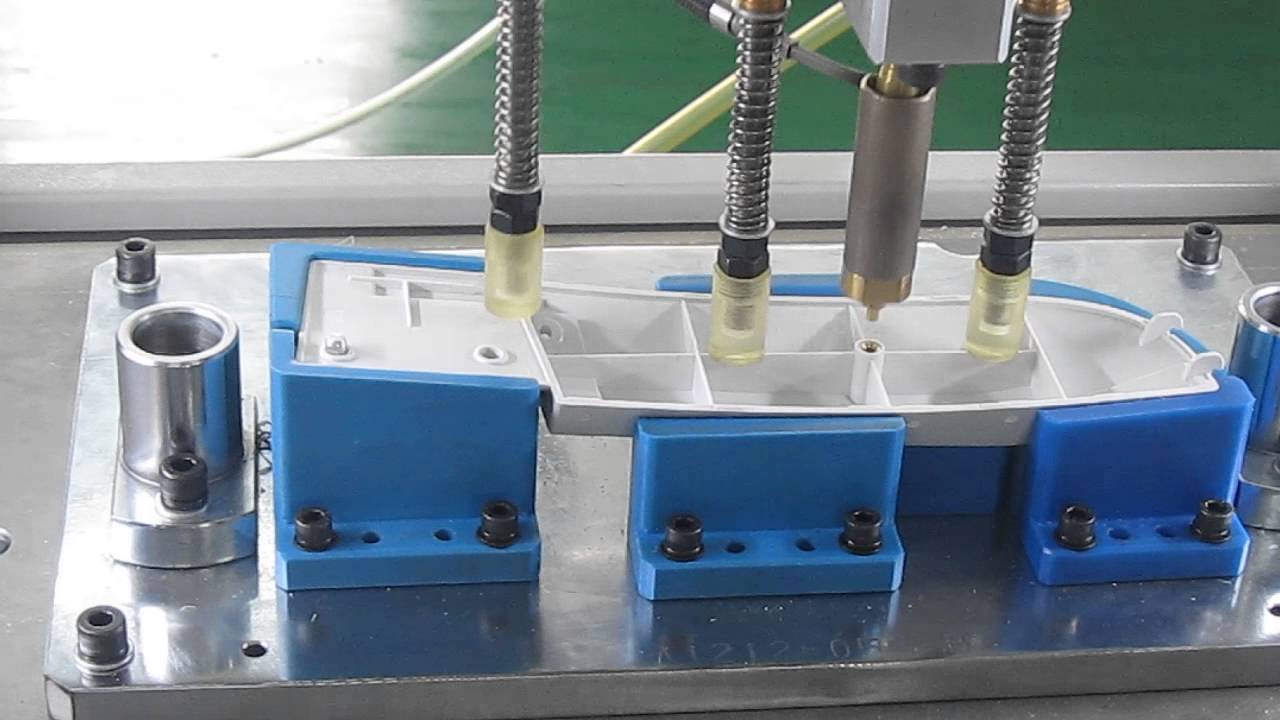

Used to bond two pieces of plastic together; produces weld that are relatively free of flash; easy to automate; particularly suitable for high volume production.

Ultrasonic welding of plastic materials creates a molecular bond within the weld seam. Longitudinal vibrations in frequencies of 20 kHz, 30 kHz, and 35 kHz with tool amplitudes between 5 µm and 50 µm are introduced into the plastic materials under the action of force. Ultrasonic vibrations are focused by means of special design of the components or tools. This specific geometry within a component is referred to as energy director. The contact points in the joining area are actively molded by means of energy input to achieve elastic deformation. Friction occurring between the contact surfaces and within the molecule chains generates heat that causes the material to melt.

Heat Insertion is a user friendly, low maintenance, repeatable method of permanently embedding a metal component into a thermoplastic product through the use of precise time, temperature, and pressure. The most common example of heat insertion applies to internally threaded metal fasteners (inserts). The insert O.D. is manufactured with various knurls, teeth, grooves and undercuts which are designed to accommodate displaced plastic to prevent rotational torque or tensile pull out.

A manual or pneumatic press has heated probes with a tapped face to accept various size insertion tips. The insertion tip is designed to rest on the top surface of the insert as well as piloting down into the internal thread. Once contact is made moderate force is applied to the insert.

The pressure for force being applied to the insert is set so that it cannot "cold press" into the part. Heated via thermal conduction the insert does not begin to install into its mating hole until it reaches the melt point of the thermoplastic material. Once the proper melt point has been achieved the heated probe advances and drives the insert to a flush or above/below flush specification.

The insert does not begin to install into its mating hole until it reaches the melt point of the thermoplastic material. Once the proper melt point has been achieved the heated probe advances and drives the insert to a flush or above/below flush specification. Heat insertion achieves the high strength values of a molded in insert while offering the benefits of post molded insertion. Heat insertion allows the fabricator to install an unlimited number of inserts of various sizes on multiple planes simultaneously. Heat Staking is also a user friendly, low maintenance, cost effective, repeatable method of mechanically attaching plastic to plastic and plastic to non-plastic products. The process combines precise pressure, temperature, time and cooling to reform a plastic stud, tab, wall, or protrusion over a mating component to retain or mechanically lock it in place.

Generally, the mating component is a dissimilar product such as printed circuit boards, metal brackets or stampings, bezels, light pipes, RF shields, or non-compatible plastic resins. Physically and visually the heat staked assembly appears to be an extension of the molding or fabricating process.

A manual or pneumatic press has heated probes with a tapped face to accept interchangeable process tips. The tip is manufactured with various contours, conical cavities, knurled patterns, or specific profiles. Once heated via thermal conduction, the tip is used to melt, form, and solidify the plastic stud which protrudes through a hole in the mating component. The molten stud under heat and pressure compresses and takes the shape of the tip cavity. At this point our unique "freeze out" feature rapidly cools the tip and solidifies the plastic under clamping pressure. This ensures a tight assembly and excellent tool release from the plastic which prevents sticking or stringing on the forming tool.

Until recently, the majority of staking was done with ultrasonic welding. With today's sophisticated microprocessor based temperature controllers, precision dwell timers, and other combined technologies, heat staking offers many advantages, such as the ability to simultaneously perform many stakes on varying planes of a product as well as independently control each staking point.

Adhesive bonding is used to fasten two surfaces together, usually producing a smooth bond. This joining technique involves glues, epoxies, or various plastic agents that bond by evaporation of a solvent or by curing a bonding agent with heat, pressure, or time.

Historically, glues have produced relatively weak bonds. However, the recent use of plastic-based agents such as the new “super-glues” that self-cure with heat has allowed adhesion with a strength approaching that of the bonded materials themselves. As a result, gluing has replaced other joining methods in many applications—especially where the bond is not exposed to prolonged heat or weathering.

A large fraction of modern glues are carbon-based petrochemical derivatives. These can be used to bond almost any combination of surfaces, either by direct contact or by fastening both surfaces to a third as with adhesive tapes. Glues can serve as bonding agents in strong structural materials—one of the earliest, and still common use is the fabrication of plywood. Other related composites include fiberglass and various fiber-epoxies such as boron-epoxy and carbon-epoxy.

Many of these materials make superior stress-bearing components. Whether bonding metal to metal, plastic, glass, rubber, ceramic, or to another substrate material, adhesives distribute stress load evenly over a broad area, reducing stress on the joint. As they are applied inside the joint, adhesives are invisible within the assembly. They resist flex and vibration stresses, and form a seal as well as a bond, which can protect the joint from corrosion.

Adhesives easily join irregularly shaped surfaces, increase the weight of an assembly negligibly, create virtually no change in part dimensions or geometry, and quickly and easily bond dissimilar substrates and heat sensitive materials. Adhesives are one-size-fits-all, and assembly can be easily automated. Limitations include the amount of time required for adhesives to fixture and develop full strength, surface preparation requirements, and the problems associated with joint disassembly.

Metal Finishing and Plating

We want to provide your parts finished, per print and that includes finishing the metal.

Standard Metal Plating

Tin

• Bright (Mil-T-10727, Type 1)

• Dull electro tin

Tin/Lead

• 60/40

• 63/37 (eutectic)

• 90/10

Copper

Nickel

• Electroless (Mil-C26074)

• Electrolytic (Mil-QQN-290)

Precious (noble) Metal Plating

Gold

Hard gold (Mil-G45204 Types 1&2, Grades B&C)

Soft gold (Mil-G45204 Type 3, Grade A)

Silver

• Matte finish (Type 1)

• Bright finish (Type 3)

Platinum

Palladium

Rhodium

Other Metal Finishing Options

• Anodizing

• Blackening

• Black oxide on copper and brass (Mil-F-495)

• Black zinc on steel (Mil-QQZ-325)

• Electropolishing

• Painting

• Passivation

• Selective Plating

• Teflon

• Tumbling

And many more! Contact Sales.

Metal Finishing & Plating Descriptions:

Tin:

Electro-tin plating is used for excellent solderability and corrosion resistance.

Tin/Lead:

Electro-tin plating is used for excellent solderability and corrosion resistance. This option is NOT RoHS compliant.

Zinc Plating

Zinc plating is the process that involves electrolytic application of zinc to metal by immersing clean steel parts into a zinc salt solution and applying electric current into it. This immersion produces zinc coatings that prevent oxidation of the protected metal. Zinc coating acts as a barrier and as a sacrificial anode when this barrier is damaged. Zinc is the best ally of steel to combat its natural enemy: corrosion.

Nickel:

Nickel plating is generally used to improve corrosion and wear resistance of the underlying base metal. Electroless Nickel ( Mil-C-26074) is good on flat or gently formed parts. Electroplated Nickel (QQ-N-290) is also available. Both types of nickel plating are not recommended on parts with sharp, formed features as the brittle plating will crack when the part is formed. Appearance of nickel can be similar to stainless steel in color, or an almost white, dull-grey color. Nickel plating is magnetic. Specify thicknesses ranging from 100u” up to 600u” and up.

Gold:

Gold plating is used in electronic parts where electrical conductivity and high corrosion resistance are required. Under Mil-G-45204 are Types I and II, grades B & C are known as hard gold Type III, grade A is known as soft gold (best used for wire bonding). If all you need is a gold flash, only 3 to 5 millionths of an inch of Type I, grade B is needed. Specify thickness from 10u” up to 100u”.

Silver:

Silver plating such as matte finish silver (Type I) and bright finish silver (Type III) are sometimes used where high electrical conductivity and excellent solderability (but decreases with age) are required. Has good corrosion resistance, depending on base metal. QQ-S-365. Specify thicknesses from 100u” up to 1000u”.

Anodizing:

Anodizing, an electrolytic process, converts aluminum surfaces to aluminum oxide. A hard coating, and resistant to corrosion. The process changes the molecular structure of the metal surface, giving it a thin, protective film. Anodized finishes are usually colorless, but can be dyed in a variety of colors. Aluminum is often anodized, as is titanium, magnesium and tantalum.

Blackening (Black Oxide):

For ferrous metals, a black, uniform coating commonly used for decorative purposes. Can provide very limited corrosion protection. Used to reduce light reflection, the more popular types of blackening are black oxide on copper and brass (Mil-F-495) and black zinc on steel (QQZ-325).

Electropolishing:

Electropolishing is widely used to provide parts a shiny and smooth surface, this process removes a few layers of atoms from a part (typically .0002″-.0005″), smoothing the surfaces and rounding the edges.

Painting:

Hi-Rel Plastics & Molding, Inc. can fully or selectively paint your part. If you have ½ etch features, we can paint and fill. If you have a specific paint color in mind, please provide the Pantone number.

Passivation:

Passivation is primarily used for cleaning and descaling stainless steel parts. While cleaning provides an enhanced appearance to the metal, it also ensures maximum corrosion resistance and prevents product contamination. MIL-S-5002.

The stainless steel passivation process removes "free iron" contamination left behind on the surface of the stainless steel which result in premature corrosion. In addition, the passivation process facilitates the formation of a thin, transparent oxide film that protects the stainless steel from selective oxidation (corrosion).

Selective plating:

Hi-Rel Plastics & Molding, Inc. can etch your part, then selectively mask and plate onto your part. Works will most types of plating (electrolytic, electroless).

Tumbling:

Tumbling is used to give parts a smoother surface area, to clean, and to break sharp edges. Parts are mixed in a vibratory tumbler with a selected media.

Assemble multiple parts that we fabricate; combining our parts with an outside vendor's; efficient staff will assemble them to your specifications.

Complete Product Assembly Services for Quality Parts and Equipment

From start to finish, Hi-Rel Plastics & Molding Inc. can provide complete product assembly, or even custom machine assembly. By combining our fabrication, welding, and machine shops, we can build truly unique production parts and equipment. With all steps of the manufacturing process under one roof we can provide a cost-effective finished product with special attention to quality, production deadlines, and the feasibility of end use.

Our custom manufacturing company employs a multi-talented crew that can take care of all your product assembly needs.

• Plastic Parts Assembly

• Metal Parts Assembly

• Chassis Assemblies

• Mechanical Assembly

• Cable Assembly

• System Wiring

• Final Assembly

• Proprietary Equipment Assembly

• Electrical Assemblies Including UL Certification through a 3rd Party

We’ll deliver quality products every time.

The Best Assembly Services at the Right Price

From Factory Floor to Your Client’s Door

Not only can we produce and assemble your products or machines, but we can even ship it straight to your customer to save you time, money and the hassle of hiring additional shipping services.

Why Deal With More Than One Manufacturer?

No matter what part of the product production process you need done, we can help. Our engineers and designers can take a rough sketch or scale drawing and use their own experience and the latest software to come up with a design, produce a prototype, test it for functionality and feasibility and even do short-run production, assembly and painting and finishing.

Unique Packaging & Shipping For Your Products

You've chosen Hi-Rel Plastics & Molding Inc. to produce your products. You've been working hard for weeks or even months getting your plan together, now for the final phase. The packaging! The Shipping! No need to worry because Hi-Rel Plastics &Molding Inc. has you covered. We not only produce your custom products, but also provide custom designed packaging to go with them.

Below are just a few of the services that we offer our customers:

Services Offered

• Custom Header Cards with Your Logo and QR Code

• Simple Bag Packaging

• Clamshell Packaging

• Sealed Foil Bag Packaging

• Foam Packaging for delicate products

• Custom Tins

• Custom Cartons

We already know your product inside and out, so it makes it easy for us to help develop the packaging & shipping that will help you take your business to the next level! Contact us today to start making your packaging & shipping as unique as your custom product!

Custom Packaging and Shipping Benefits

Fragile objects, extra-large art pieces, or valuable items can be sensitive and prone to damages. Such items need thorough care to survive the harsh temperatures and prevent dents or scratches while on the move. They need custom packing to ensure safety from departure to arrival.

How can a Hi-Rel Plastics & Molding Inc.help you?

We will apply the correct packing technique. Its team of professional packers will use the right container for maximum security. It offers custom packaging services for any kind of item you wish to ship unharmed.

You can bring items that have the most awkward shapes and we will find a way to keep them nicely tucked for hours.

7575 JURUPA AVE,

RIVERSIDE CA 92504

PHONE: 951-354-0258

FAX: 951-688-0497

info@hirelplastics.com