- Medical

- Irrigation

- Agricultural & Farming

- Equipment

- General industrial

- Aerospace

- Automotive and defense

- Research & Lab equipments

- Electronics

- Construction

- Communications

- House wares & Consumer Products

- Cosmetics and Personal Care Products

Value Added Secondary Services

In addition to continuously improving our molding capabilities, Hi-Rel Plastics & Molding, Inc. have years of experience in proven advanced molding technologies like

The rising use of plastics in medical devices means that the capability of being sterilized is

rapidly becoming a key selection criterion for any plastic to be used in a medical device. The

objective of sterilization is to prevent the introduction into the body of pathogenic organisms

not normally present. Sterilization can be defined as ‘the removal or destruction of all living

organisms, including resistant forms such as bacterial or fungal spores’.

Bacterial spores are most resistant to destruction, and if the sterilization is effective in

eliminating bacterial spores then it can generally be assumed that all other pathogenic and

non-pathogenic organisms have been destroyed. Disinfection is a lower grade of sterilization and

involves only the destruction of pathogenic organisms in the vegetative (or non-sporing) state;

it does not involve the destruction of spores.

Sterilization is the only acceptable standard for surgical purposes although disinfection may

well be suitable for other purposes. Sterilization Methods Sterilization can be achieved through

a variety of methods and these will be considered individually with particular emphasis on the

applicability of the method to the sterilization of plastics devices. No matter which

sterilization method is used, the objective is to reduce the bioburden (the number of

microorganisms present) to a safe level. [Production in a ‘clean room’ (of any standard) does

not make a device sterile; it simply reduces the initial bioburden and concentration of foreign

particles to make sterilization more effective.]

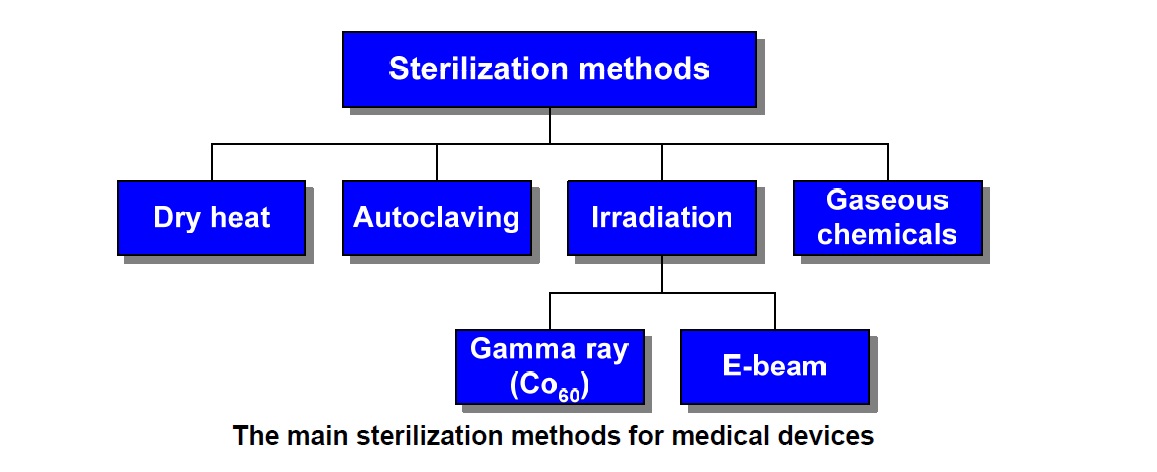

The main sterilization methods for medical devices are:

• Dry Heat

• Autoclaving

• Irradiation

• Gamma Rays

• E-beam

• Gaseous Chemicals (EtO)