- Medical

- Irrigation

- Agricultural & Farming

- Equipment

- General industrial

- Aerospace

- Automotive and defense

- Research & Lab equipments

- Electronics

- Construction

- Communications

- House wares & Consumer Products

- Cosmetics and Personal Care Products

Value Added Secondary Services

In addition to continuously improving our molding capabilities, Hi-Rel Plastics & Molding, Inc. have years of experience in proven advanced molding technologies like

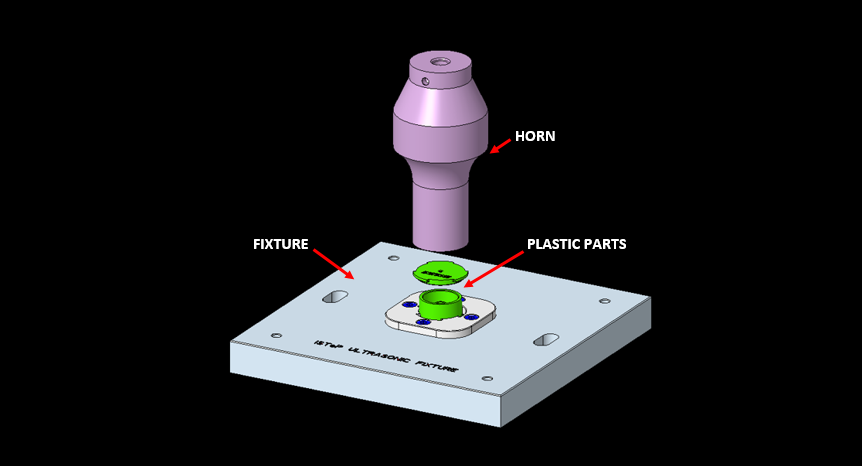

Used to bond two pieces of plastic together; produces weld that are relatively free of flash;

easy to automate; particularly suitable for high volume production.

Ultrasonic welding of plastic materials creates a molecular bond within the weld seam.

Longitudinal vibrations in frequencies of 20 kHz, 30 kHz, and 35 kHz with tool amplitudes

between 5 µm and 50 µm are introduced into the plastic materials under the action of force.

Ultrasonic vibrations are focused by means of special design of the components or tools. This

specific geometry within a component is referred to as energy director. The contact points in

the joining area are actively molded by means of energy input to achieve elastic deformation.

Friction occurring between the contact surfaces and within the molecule chains generates heat

that causes the material to melt.